CIRCULAR ECONOMY SUMMIT AUSTRIA

Status of the circular economy in Austria: Panel on circular construction, March 22, 2022

Speaker: Thomas Romm

The Circular Economy Summit Austria initiates a cross-sectoral discussion of an Austrian circular economy strategy on how resource consumption can be reduced and the circular economy strengthened. For the construction sector, we were able to show in the previous study KreislaufBauwirtschaft (Implementation of a circular economy in the construction industry) that the need for raw materials in the construction industry cannot be covered alone by closing the cycle of material flows. Cycles can only be closed if the resource requirements are reduced in such a way that the input (resource requirements) can be covered by the output (waste/secondary raw materials). The durability of buildings and the use of renewable raw materials are important fields of action in order to achieve this goal. New business models are required that target the value-added potential of urban mines. The shift to a circular economy is above all a socio-cultural shift: In addition to protecting resources, we must also focus on social added value such as employment and qualification, as BauKarussell does.

Circular Economy

From applied research, to project planning and building,

we offer a closed-loop construction consulting.

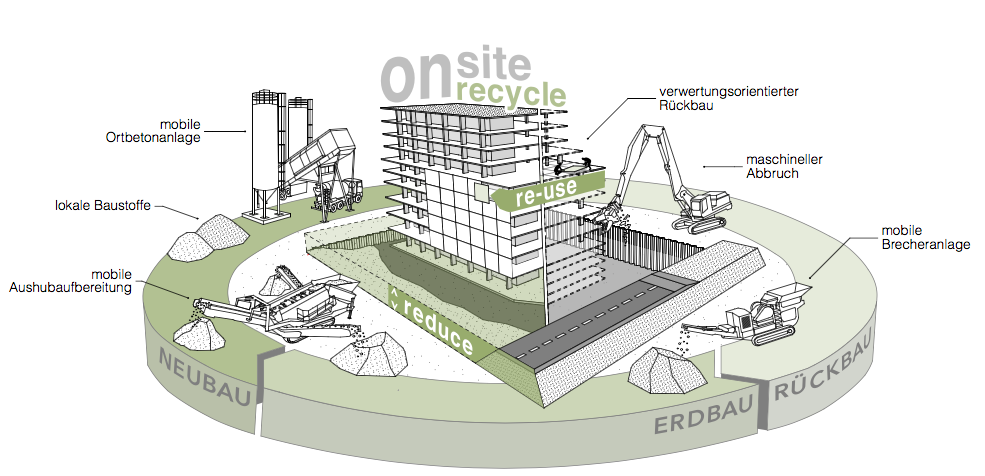

on site recycling - re-use of materials - reduction of material flows

reduction of transport volume

- mobile in-situ concrete plant

- local building materials (e. g. local gravel as concrete aggregate)

- mobile preparation plant

reduction of waste

- ecologic dismantling to enable reuse of building materials

- mobile crushing plant

- mechanical demolition for a higher efficiency regarding economic viability and sustainability

Case Study Seestadt Aspern

In the housing construction in the Seestadt Süd, 1 million tonnes of material from our own construction activities were recycled. A cleverly devised logistics system between the building sites ensured that almost all of the excavated earth was used directly on site. The in-situ concrete plant installed there processed the local gravel from the lake and the excavation pit. This was used in civil engineering for road dams, frost boxes and paved areas. This material extraction also shortens the construction time of the residential building. With this and other environmentally friendly construction measures, the construction of the residential building saved more than 100,000 heavy-duty truck trips in the city area.

Read more about the project of Seestadt Aspern!